Explore the Advancements of Laser Engraving Technology for 2025

Laser engraving technology has undergone remarkable transformations, revolutionizing manufacturing, personalization, and creative industries worldwide. As we approach 2025, cutting-edge innovations in laser systems are delivering unprecedented precision, speed, and versatility across diverse applications. From industrial manufacturing to artistic customization, these technological advances are reshaping how businesses and individuals approach material processing and design implementation.

The landscape of laser engraving continues to evolve rapidly, driven by technological breakthroughs that enhance performance while reducing operational costs. Modern laser systems now incorporate artificial intelligence, improved beam control, and advanced materials compatibility, making them indispensable tools across numerous sectors.

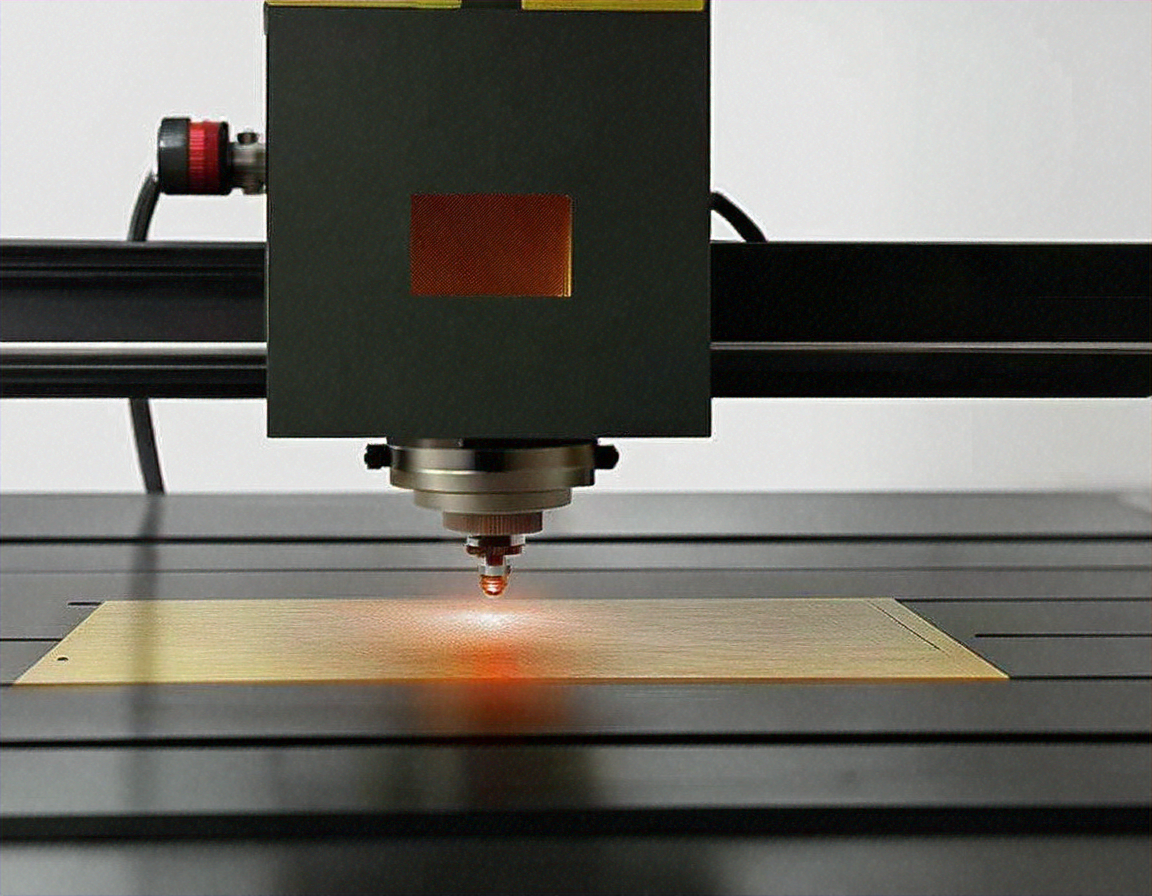

Understanding Laser Engraving Machines

Contemporary laser engraving machines utilize focused light beams to remove material surfaces with microscopic precision. These systems operate through computer-controlled movements, translating digital designs into physical engravings on various substrates. The technology encompasses multiple laser types, including CO2, fiber, and diode lasers, each optimized for specific materials and applications. Advanced machines now feature automatic focus adjustment, real-time monitoring systems, and integrated safety protocols that significantly enhance operational efficiency and user safety.

Key Features of Modern Laser Technology

Today’s laser engraving systems incorporate sophisticated features that distinguish them from earlier generations. Variable pulse control allows operators to adjust engraving depth and quality based on material requirements. Multi-axis positioning systems enable three-dimensional engraving capabilities, while advanced cooling systems maintain optimal operating temperatures during extended use. Integration with cloud-based software platforms facilitates remote operation and design management, streamlining workflow processes for businesses of all sizes.

Applications in Various Industries

Laser engraving technology serves diverse industrial applications, from aerospace component marking to medical device customization. The automotive industry relies on laser systems for part identification and decorative elements, while electronics manufacturers use precision engraving for circuit board processing. Jewelry designers leverage laser technology for intricate pattern creation, and architectural firms employ large-format systems for building material customization. Educational institutions increasingly adopt laser engraving for prototyping and creative projects, demonstrating the technology’s versatility across professional and academic environments.

Enhancing Precision with Laser Tools

Precision improvements in laser engraving stem from enhanced beam quality, improved mechanical components, and sophisticated control algorithms. Modern systems achieve positioning accuracy within micrometers, enabling detailed work on miniature components and delicate materials. Advanced optics reduce beam distortion, while vibration dampening systems minimize external interference during operation. Real-time feedback mechanisms continuously monitor engraving quality, automatically adjusting parameters to maintain consistent results throughout extended production runs.

| Machine Type | Provider | Key Features | Cost Estimation |

|---|---|---|---|

| CO2 Desktop System | Epilog Laser | 40W power, 24”x12” bed | $15,000-$25,000 |

| Fiber Laser Marker | Trotec | High-speed marking, metals | $35,000-$50,000 |

| Industrial Engraver | Universal Laser | Large format, multi-material | $75,000-$150,000 |

| Compact Diode Unit | Glowforge | User-friendly, cloud-based | $3,000-$8,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

The Future Trends in Laser Engraving

Emerging trends in laser engraving technology point toward increased automation, enhanced material compatibility, and improved energy efficiency. Artificial intelligence integration will enable predictive maintenance and automatic parameter optimization based on material properties and design requirements. Hybrid systems combining multiple laser types within single platforms will expand processing capabilities, while sustainable practices drive development of energy-efficient laser sources. Advanced materials processing, including ceramics and composites, will open new application possibilities as laser technology continues advancing toward 2025 and beyond.

The convergence of laser engraving technology with digital manufacturing ecosystems positions these systems as cornerstone tools for future production environments. As precision requirements increase and customization demands grow, laser engraving technology will continue adapting to meet evolving industry needs while maintaining the reliability and versatility that have established its prominence across global markets.