The Basics of Laser Cutting and Engraving: A Comprehensive Guide

Laser cutting and engraving have revolutionized the world of personalization and manufacturing. This versatile technology offers precision, speed, and creativity for both hobbyists and professionals alike. In this comprehensive guide, we'll explore the fundamentals of laser cutting and engraving, their applications, and how you can leverage this technology for personal and commercial use.

What is laser cutting and engraving?

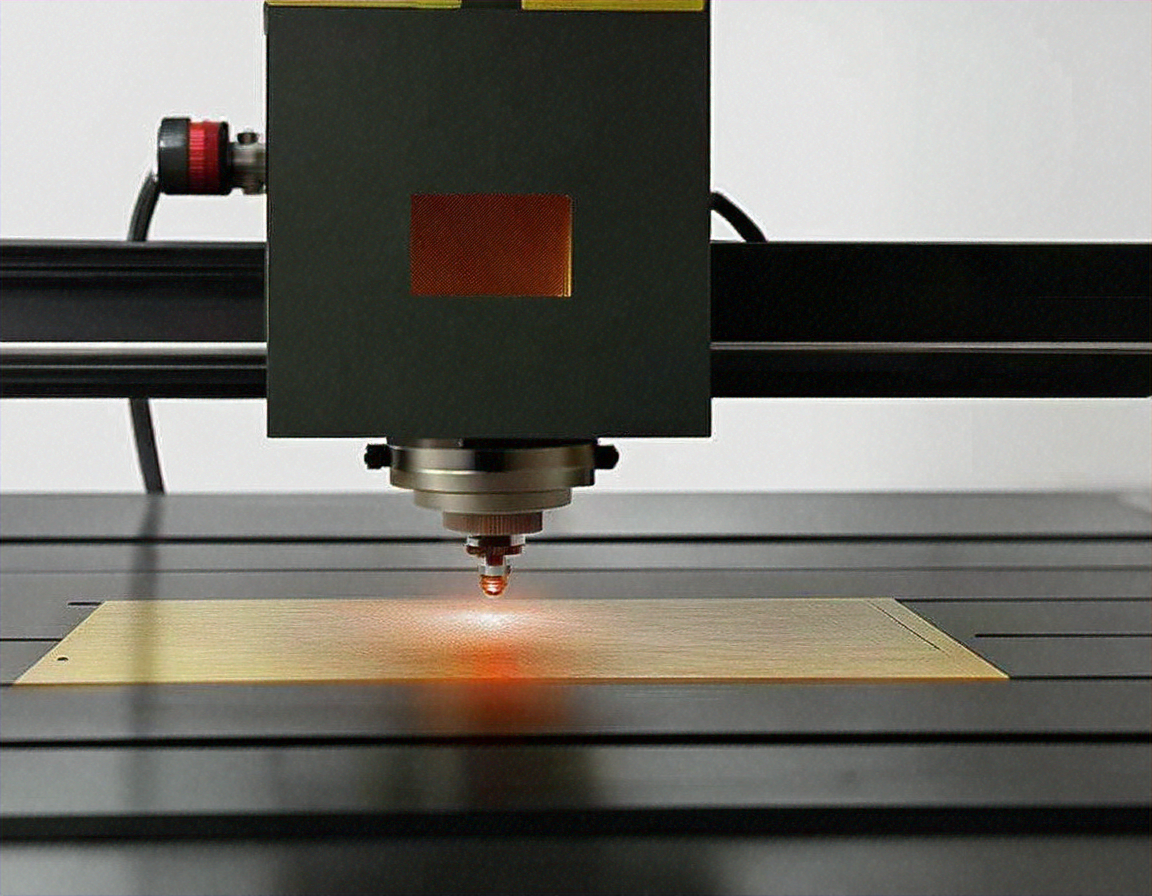

Laser cutting and engraving are processes that use high-powered lasers to cut, etch, or mark materials with extreme precision. The laser beam is focused on a small area, generating intense heat that vaporizes or melts the material, allowing for intricate designs and patterns to be created. This technology can be used on a wide range of materials, including wood, acrylic, metal, glass, and fabric.

How does laser cutting differ from engraving?

While both processes use laser technology, there are key differences between cutting and engraving:

-

Laser Cutting: This process involves using the laser beam to cut completely through the material, creating separate pieces or intricate shapes.

-

Laser Engraving: In this technique, the laser beam removes a layer of material to create a permanent, raised design on the surface without cutting through it entirely.

The choice between cutting and engraving depends on the desired outcome and the material being used.

What are the advantages of laser engraving and cutting?

Laser engraving and cutting offer several benefits over traditional methods:

-

Precision: Lasers can create highly detailed and accurate designs, even on a microscopic scale.

-

Versatility: A single machine can work on various materials and perform both cutting and engraving tasks.

-

Speed: Laser technology allows for quick production, especially for complex designs.

-

Non-contact process: Since there’s no physical contact between the tool and the material, there’s less wear and tear on equipment.

-

Minimal material waste: Laser cutting is highly efficient, resulting in less material waste compared to traditional cutting methods.

-

Customization: Laser technology makes it easy to create personalized and unique items quickly and cost-effectively.

How to create personal gifts using laser engravings

Laser engraving opens up a world of possibilities for creating unique and personalized gifts. Here are some ideas to get you started:

-

Customized photo frames: Engrave names, dates, or special messages on wooden or acrylic frames.

-

Personalized jewelry: Create one-of-a-kind pendants, bracelets, or rings with engraved designs or text.

-

Custom cutting boards: Engrave family recipes or meaningful quotes on wooden cutting boards.

-

Engraved glassware: Personalize wine glasses, beer mugs, or champagne flutes with names or special occasions.

-

Customized phone cases: Design and engrave unique patterns or text on phone cases.

To create these gifts, you’ll need access to a laser engraving machine and design software. Many makerspaces and local workshops offer laser engraving services if you don’t own a machine.

Laser cutting machine price and factors to consider

When considering purchasing a laser cutting machine, several factors affect the price:

-

Power output: Higher wattage machines are more expensive but can cut thicker materials and work faster.

-

Work area size: Larger cutting areas increase the machine’s cost.

-

Type of laser: CO2 lasers are common for hobbyists and small businesses, while fiber lasers are used for metal cutting and industrial applications.

-

Additional features: Auto-focus, rotary attachments, and air assist systems can add to the cost.

-

Brand and quality: Well-known brands with reliable customer support often come at a premium.

| Machine Type | Power Range | Typical Price Range | Best For |

|---|---|---|---|

| Desktop CO2 Laser | 30-60W | $300 - $3,000 | Hobbyists, small businesses |

| Mid-range CO2 Laser | 60-150W | $3,000 - $15,000 | Small to medium businesses |

| Industrial CO2 Laser | 150W+ | $15,000 - $50,000+ | Large-scale production |

| Fiber Laser | 20-500W | $5,000 - $100,000+ | Metal cutting, industrial use |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

When choosing a laser cutting machine, consider your specific needs, budget, and long-term plans. For beginners or hobbyists, a desktop CO2 laser cutter might be sufficient, while businesses may need to invest in more powerful and versatile machines.

Laser cutting and engraving technology offers a world of creative possibilities for both personal and professional use. By understanding the basics, advantages, and considerations involved in laser technology, you can make informed decisions about incorporating this versatile tool into your projects or business operations. Whether you’re creating personalized gifts or running a manufacturing operation, laser cutting and engraving can help you achieve precision, speed, and unique designs that were once impossible with traditional methods.